Global Supply Chain Management: Effects from a Pandemic

Tables of Contents

The global supply chain helps make manufacturers and industries more efficient and profitable by reducing costs and encouraging businesses to expand into international markets. The goal of global supply chain management is to ensure that the international networks of manufacturers, vendors, warehouses, transportation companies, distributors, and retailers operate smoothly.

An important element of that goal for business managers is to mitigate the risks entailed in relying on suppliers and other partners whose operations are a world away and who are subject to rules and regulations of different governments. One risk few businesses calculated was the impact of a pandemic on global supply chains.

A November 2020 study by the U.S. Cybersecurity and Infrastructure Security Agency (CISA) reports on the disruptions to the global supply chain as a result of COVID-19:

- A survey of 450 executives across industries found that 62% of firms experienced supply chain disruptions that ranged between 20% and 80% of total volume.

- When asked which supply chain vulnerabilities were brought to light by the pandemic, 46% of the executives cited dependency on unreliable partners or governments.

What Is Global Supply Chain Management?

Globalization has been a prevailing trend in nearly every industry for the past several decades as manufacturers and other businesses attempt to take advantage of the abundant raw materials and low-cost manufacturing available in developing countries around the world. Global supply chains are the sophisticated networks of manufacturing, logistics, transportation, and communication firms that move products and material through worldwide production and distribution channels.

Global supply chain management is the process of ensuring the secure and timely delivery of everything from raw materials to finished consumer goods as they travel from manufacturers and suppliers to wholesalers, retailers, and other distribution points. The goals of supply chain managers are to reduce costs, improve efficiency, and mitigate risk.

How Supply Chains Work and Why They Are Important

Supply chains are the networks that link business partners as they produce products and services and deliver them to their customers, whether consumers or other businesses. Investopedia describes the many activities, entities, and resources that are involved in domestic and global supply chains:

- Moving raw materials and converting them into finished products

- Transporting the products to distribution sites

- Distributing the products to customers

- Coordinating the work of suppliers, manufacturers, vendors, warehouses, transportation partners, wholesalers, and retailers

- Managing the logistics of product development, marketing, finance, customer service, business operations, and distribution

Global Supply Chains Before and After the COVID-19 Outbreak

The critical importance of supply chain management to the global economy was evident to businesses and industries long before the COVID-19 pandemic struck, yet many manufacturers across industries continued to rely on a single source for their supply of vital products and materials. The widespread use of just-in-time (JIT) production models that minimize inventory in an attempt to reduce costs also made companies more vulnerable to potential supply chain disruptions, as the law firm Foley & Lardner reports.

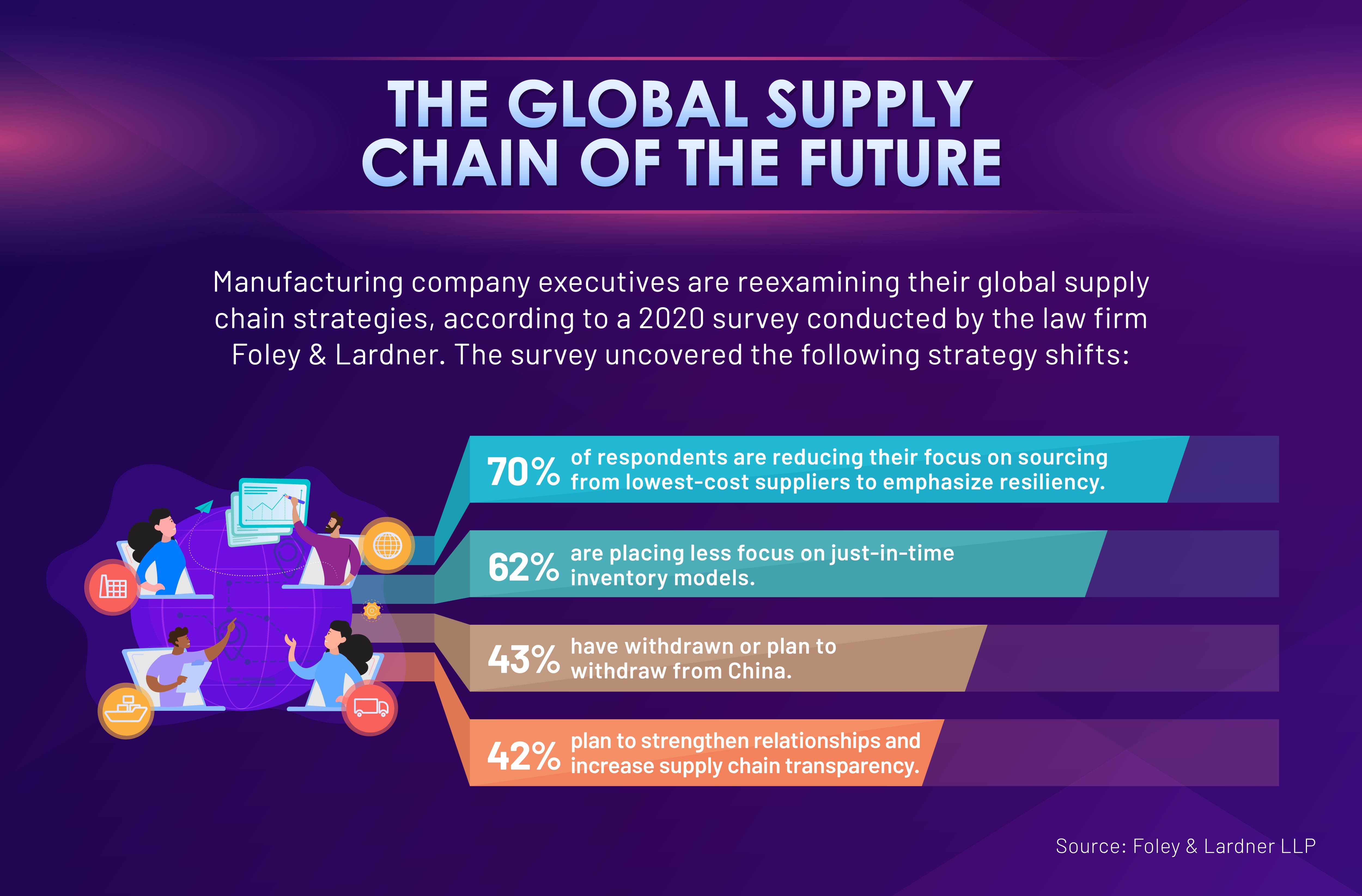

The results of an executive survey released by Foley in September 2020 indicates that businesses have already begun to deemphasize cost savings in favor of improving their resilience and reducing their dependence on production or sourcing from China:

- Close to half of the executives surveyed (43%) state their companies have already removed some production or sourcing from China or intend to do so.

- Nearly one in three executives (62%) indicate that their companies will deemphasize JIT manufacturing.

Manufacturing company executives are reexamining their global supply chain strategies, according to a 2020 survey conducted by the law firm Foley & Lardner. The survey uncovered the following strategy shifts: 70% of respondents are reducing their focus on sourcing from lowest-cost suppliers to emphasize resiliency; 62% are placing less focus on just-in-time inventory models; 43% have withdrawn or plan to withdraw from China; and 42% plan to strengthen relationships and increase supply chain transparency.

Why Global Supply Chains Are Increasingly Important to Manufacturers

The globalization that opened supply chains to countries around the world created tremendous economic opportunities for many regions and industries. The trend toward open international markets progressed steadily in the period after World War II, but recent political shifts have combined with pressure from the pandemic to disrupt established supply chain links across countries, continents, and political systems.

High-tech manufacturers in particular rely on raw materials that are available primarily through global partners. Foreign Policy reports on intensifying efforts by U.S. technology firms to find more accessible sources of the rare earth elements needed to produce the sophisticated equipment that drives the computer, electronics, and defense industries. At present the U.S. relies on China and other foreign countries for supplies of these vital raw materials.

Global Supply Chain Issues Caused by the Pandemic

Businesses’ emphasis on cost savings in their global supply chain management strategies has led to them relying on a single supplier or manufacturer for all their resource needs, from raw materials to finished products. Single sourcing all the components needed to assemble a product saves manufacturers money.

While natural disasters, extreme weather, and other events have affected the global supply chain in the past, the movement of people and goods around the world has never been impacted by a catastrophe with the breadth and scope of the COVID-19 pandemic. Supply & Demand Chain Executive lists four global supply chain issues that explain why the pandemic’s impact on global trade is so devastating:

- Geographic scope: No previous natural disaster has impacted the entire global population the way COVID-19 has.

- Industrial scope: Most disasters and other disruptions affect a handful of industries directly and others indirectly, but COVID-19’s impact is felt firsthand by all industries and markets.

- Demand shame: Demand for high-end items has dried up as consumers with high disposable incomes choose to cancel or delay planned purchases of luxury items.

- Duration: Even natural disasters as devastating as the earthquakes and tsunamis that struck in Indonesia in 2004 and Fukushima, Japan, in 2011 take most nations only a few years to recover from. COVID-19’s impact on global supply chains and economies is expected to be felt for a decade or longer.

How Manufacturers Are Affected by and Are Responding to the Pandemic

Events such as the COVID-19 pandemic highlight just how fragile global supply chains can be.

- Shortages of personal protective equipment (PPE), medical testing equipment, dialysis products, pharmaceuticals, and other vital medical supplies are the result of dependence on unreliable foreign sources for these products. One long-term solution is to emphasize the use of products that can be reused or repurposed.

- The pandemic has devastated the food and beverage industry, diminishing operational capacity “from farm field to consumer,” as Supply Chain Management Review Production, processing, packaging, and distribution are more expensive due to new rules mandated by COVID-19, and stay-at-home orders have driven plummeting demand for food service at restaurants.

- A shortage of semiconductors caused by COVID-related supply chain disruptions has forced auto manufacturers to shutter some manufacturing plants. Ford Motor announced a one-week closure of a plant in Louisville, Kentucky, due to the shortage, and both Fiat Chrysler and Toyota North America have postponed plant openings as a result of the lack of semiconductor supply.

To counter the economic impact of COVID-19, manufacturers and other businesses are taking advantage of opportunities to make meaningful changes to their operations. Accenture identifies five priorities for improving the supply chain:

- Keep workers healthy and productive by promoting new ways of doing their jobs.

- Improve the visibility of the data related to demand, inventory, capacity, and finances.

- Identify the most profitable micro-segments of the market via careful data analysis.

- Prepare for future disruptions by organizing quick-action teams trained to handle a range of contingencies.

- Envision supply chain scenarios and develop plans based on optimal responses to various situations.

Keeping Supplies Flowing While Protecting Workers

The U.S. and other countries face serious challenges as they work to keep critical manufacturing and other supplies flowing while protecting workers and preventing the spread of the virus. Restrictions on human travel to minimize virus transmission didn’t extend to the shipment of goods through U.S. ports.

The challenge for manufacturers is to maintain operations without imperiling their employees’ health. PricewaterhouseCoopers reports that U.S. manufacturers employ 13 million workers, with few who can work off-site. The heightened risk of virus spread among workers has led many manufacturers to investigate automation technologies such as robotics and autonomous materials movement to separate workers in manufacturing environments.

How the Pandemic Laid Bare Global Supply Chain Vulnerabilities

Prior to COVID-19, manufacturers stressed reducing costs above all other goals. This led to an overreliance on single-source suppliers, too much emphasis on the lowest bids, and a lack of transparency in the supply chain. National Defense Industries Association vice president David Chesebrough states that JIT and other cost-saving approaches “introduced a great deal of fragility” into the global supply chains that manufacturers depend on.

The supply of products and materials such as medical equipment and supplies, critical security equipment, and electronic and computer components quickly dried up when the pandemic struck in early 2020. In addition, supply chains were vulnerable to vendors selling counterfeit products due to the lack of transparency in the operations of international partners, as Institute for Supply Management CEO Thomas Derry points out.

Economic and Social Impact of Supply Chain Disruptions

Most large multinational corporations have the resources they need to weather the disruptions caused by the pandemic. In some cases, large firms have seen profits increase, such as Amazon and Walmart. Conversely, small businesses have taken the brunt of the economic fallout resulting from COVID-19. In his testimony to a congressional hearing on supply chain resiliency, Brookings senior fellow Eswar Prasad stated that the pandemic has had “a much sharper deleterious effect on small businesses than on large corporations.” Prasad points out that small businesses represent 40% of the U.S. gross domestic product and employ half of all workers in the U.S.

The pandemic has also affected the financial stability of U.S. manufacturers’ trading partners. The Organization for Economic Cooperation and Development (OECD) forecasts the long-term impact of COVID-19 on international trade:

- For many countries, economic output will be 5% lower in 2022 than pre-pandemic forecasts.

- Small firms and entrepreneurs will be more likely to fail than large corporations.

- Many of the low-wage earners who lost their jobs due to COVID-19 will find it difficult to find new jobs in the short term.

- Poor people will see their standard of living decline, and those without ready access to the internet will struggle to learn or work from home.

The pandemic has also deterred efforts to thwart child labor and address poor working conditions. UNICEF USA reports that in many countries declines in household incomes put added pressure on children to join the workforce. The organization states that roughly half of the 152 million children currently working are doing so under hazardous conditions, such as working in farm fields and picking through trash.

Global Supply Chain Examples

Prior to the COVID-19 outbreak, Gartner’s Supply Chain Top 25 for 2020 identified three key trends in the global supply chain:

- Closer ties to partner firms based on customer needs and enhanced transparency

- Increased use of advanced data analytics to improve the efficiency of supply chain management

- More focus on corporate social responsibility

The Gartner study highlights three global supply chain examples of leadership trends:

- Companies are striving to become more purpose-driven and socially responsible rather than focusing solely on maximizing shareholder value.

- They are working to transform the supply chain business model to make it more agile and resilient.

- They are increasing their investments in real-time visibility and more accurate planning by applying advanced data analytics, robotic process automation, and other artificial intelligence-based technologies.

How the Global Supply Chain Operates in Specific Industries

While supply chains across industries share many characteristics, industry-specific elements can present unique challenges in the event of disruptions such as the COVID-19 pandemic. For example, the food industry must ensure the freshness of the products it ships, while high-tech industries’ primary supply chain goals include securing adequate reliable sources of rare materials.

- Automotive industry: Demand has remained strong for automobiles and other motor vehicles, but disruptions to the industry’s supply chain have caused a shortage of new vehicles. While pandemic-related work restrictions contribute to the shortfall in inventory, the primary cause is lack of parts from suppliers in China and other Asian countries.

- Food industry: The pandemic has increased U.S. consumer grocery store spending and decreased their spending at restaurants and other food services. The resulting disruption to the food supply chain caused food services to cancel orders. Food distributors struggled to balance inbound orders from farmers with new logistics procedures required to serve their grocery store clients.

- Computer and communications industries: Many technology firms learned the dangers of an overly complex global supply chain in the aftermath of the COVID-19 outbreak, as CISA reports. In particular, a lack of transparency relating to second- and third-tier suppliers has left many firms vulnerable to shortages of critical components. CISA points out that some tech products rely on components from hundreds of different suppliers to reach their finished state.

How Companies and Industries Are Responding to Supply Chain Disruptions

Companies and industries are taking many different approaches as they work to overcome disruptions to their global supply chains caused by COVID-19 precautions. For example, Maryville University associate professor Richard Kilgore tells transportation news service FreightWaves that the automotive industry may require “months or years … in terms of ramping up production levels to anywhere near pre-pandemic production levels.”

Professor Kilgore goes on to state that “with long-term uncertainty on the demand side, it is likely that capacity reduction, as well as consolidation,” will be part of automobile manufacturers’ plans for a post-COVID recovery. He notes that since the industry was “already seeing sales and production declines in 2019, some may see this as the appropriate time to negotiate closures with union, government, and other stakeholders, whereas in normal times those might have been more of an obstacle.”

Domestic vs. International Supply Chain Management Challenges

The initial response of many U.S. policymakers to the supply chain disruptions resulting from COVID-19 restrictions was to call for “reshoring” supply chains for goods deemed critical, such as medical supplies and high-tech products. However, pandemic-related disruptions also affected domestic supply chains. The reality of domestic vs. international supply chains shows that relying solely on domestic sources for such products would put U.S. firms at a competitive disadvantage in global markets.

The efficiencies and benefits of moving goods within the U.S. as compared to transporting them between the U.S. and other countries depends in large part on the characteristics of the products:

- Functional products are those with long life cycles and little demand variability; they are most suitable for the cost efficiencies of offshore supply chains.

- Innovative products typically have short life cycles and a high level of demand variability; they call for market-responsive supply chains relying on near-shored or domestic supply chains.

- Critical products relate to security, defense, health, and national competitiveness; their supply chains must be monitored by the government for national security purposes.

Resources on the Impact of COVID-19 on Global Supply Chains

- Institute for Operations Research and the Management Sciences, “COVID-19 Supply Chain Resources” — Peer-reviewed scientific research and multimedia resources cover all aspects of the pandemic’s impact on global supply chains.

- World Economic Forum, “The Ongoing Impact of COVID-19 on Global Supply Chains” — The impact of the pandemic on trade wars, global politics, and government trade policies is examined in terms of the steps businesses can take to mitigate future disruptions.

- Association for Supply Chain Management, “Recovering from the Impact of COVID-19” — Topics that include preparing the global supply chain for the rollout of COVID-19 vaccines and steps for adopting digital supply chain management strategies are discussed.

Global Supply Chain Management in a Post-Pandemic Economy

As manufacturers and other businesses around the world struggle to maintain their operations under restrictions mandated by the battle against the deadly coronavirus, they must also prepare their supply chains for the post-pandemic economy. Harvard Business Review forecasts that in the pandemic’s aftermath, manufacturers will be under “greater political and competitive pressures to increase their domestic production” and promote employment in their home countries.

However, many aspects of the global supply chain will remain unchanged once COVID-19 has been tamed, such as competitive price pressures and the drive to improve operational efficiencies. The first step in creating a robust global supply chain is to identify hidden vulnerabilities, many of which exist not in the first or second tier of the supply chain but at lower levels that are often invisible to manufacturers.

How Recent Changes Will Impact the Post-Pandemic Global Supply Chain

Recent COVID-related trade rules and procedures will impact the economy for many years to come. Many of the changes to supply chain management resulting from the pandemic were underway before the virus struck. The pandemic served to speed up the shift among manufacturers to responding more quickly to changing customer values and purchasing habits, for example. This applies whether their customers are consumers or other businesses.

- Companies will place greater emphasis on earning customers’ trust by demonstrating shared values and corporate purpose in addressing social ills.

- Sales channels are merging, which requires that manufacturers and vendors adopt omnichannel approaches to distribution and marketing.

- Digital supply networks (DSN) will break down the functional silos that have dominated global supply chains in the past, both within organizations and between business partners.

- Companies will attempt to limit the number of tiers in their global supply chain and to learn more about their direct suppliers and the firms that supply their suppliers.

Supply Chain Problems Exposed by the Pandemic

CISA’s report on the supply chain disruptions that resulted from the pandemic identifies three areas of weakness that COVID-19 exposed:

- Over-reliance on JIT inventory management to cut costs made manufacturers vulnerable to interruptions in the supply chain. CISA notes that inventory is expensive, and holding large inventories can make companies less attractive to investors. The pandemic has reset the balance between efficiency and resiliency.

- The lack of supply chain transparency prevents manufacturers from adequately tracking second- and third-tier suppliers. Companies at the end of the supply chain need ways to know when suppliers at any level of the process, including those they don’t deal with directly, may be unable to meet their obligations.

- The desire to reduce costs and secure a sufficient supply of needed products leads to reliance on a single source or geographic region for critical supplies. However, the practice increases a manufacturer’s risk of an operations interruption. The problem is especially pronounced in high-tech industries that require large amounts of commodities such as gold, silver, lithium, and silicon, which are often available only from a small number of countries.

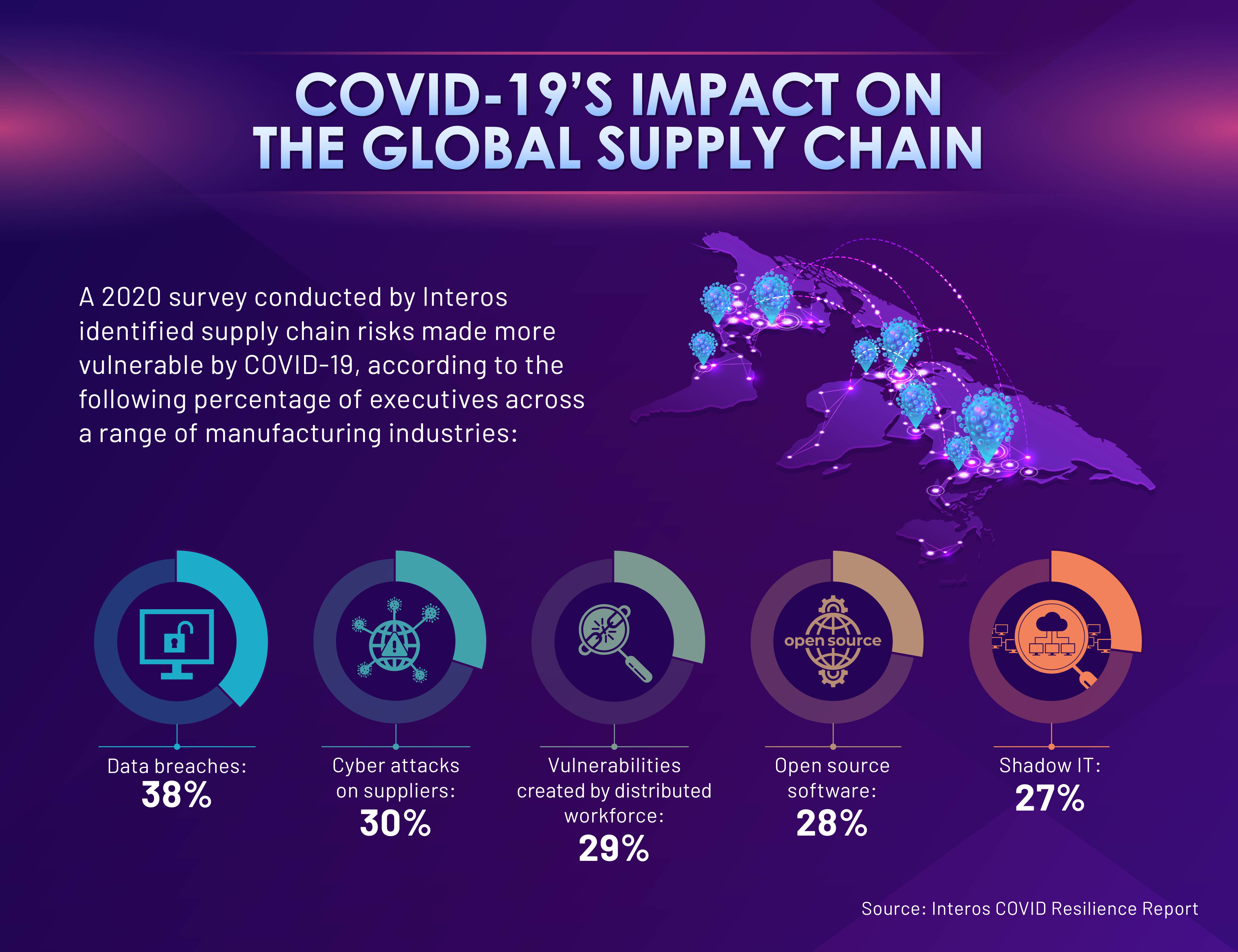

A 2020 survey conducted by Interos identified supply chain risks made more vulnerable by COVID-19, according to the following percentage of executives across a range of manufacturing industries: data breaches, 38%; cyber attacks on suppliers, 30%; vulnerabilities created by distributed workforce, 29%; open source software, 28%; shadow IT, 27%.

How New Technologies Will Impact the Global Supply Chain

Supply chains have become so complex that “only machines can do the work of keeping track of all this information,” according to the World Economic Forum. Predictive Analytics Today describes the ability of supply chain management software to automate all the transactions and activities that are involved in connecting manufacturers with their suppliers.

- Inventory management tracks the availability of stock and raw materials and also analyzes trends to help determine future needs.

- Warehouse management monitors a company’s physical storage facilities for security as well as labor and other associated costs.

- Customer requirement process manages the supply chain in terms of how well it meets customers’ needs all the way to delivery of the final product.

- Sourcing and supplier management includes tools that help manufacturers identify viable suppliers and establish good working relationships.

These are among the leading supply chain management software vendors:

- E2Open offers cloud-based logistics, transportation management, and supply chain management.

- Logility makes AI-based tools for planning supply chains via machine learning.

- SAP Ariba is called an “intelligent spend management” solution that integrates supplier management, including sourcing, procurement, and financing.

- Blue Yonder applies machine learning to resolve supply chain disruptions, reduce expediting expenses, and improve planning efficiency.

- Infor Financials & Supply Management combines enterprise resource planning (ERP) with supply chain management and financial and accounting functions.

Resources on the Outlook for Global Supply Chain Management

- Supply Chain, “The Global Supply Chain Technology Outlook 2021” — Six trends expected in 2021 are analytics and analysis, AI, blockchain technology, Internet of Things, Internet of Behaviors, and robotic process automation.

- SupplyChainBrain, “Seven Supply-Chain Trends to Watch in 2021” — Among the trends identified are smart contracts, agile supply chains, and the layering of multiple technologies to eliminate data silos.

- Institute for Management Development, “A Post COVID-19 Outlook: The Future of the Supply Chain” — Industry predictions include a shift from globalization to regionalization, adoption of supply chain stress tests, and a greater appreciation for the human factor in decision-making.

The Skills Managers Will Need to Thrive in Tomorrow’s Economy

The magnitude of COVID-19’s supply chain disruption caught manufacturers unprepared. The inability of the statistical models and modern data analytics techniques to anticipate such massive breaks in business processes highlights the importance of business managers in helping companies plan for unexpected industry-shaking changes to their operations in domestic and international markets.

Countries will continue to trade, and supply chains will continue to span nearly all corners of the globe, despite the pandemic’s expected repercussions. In the catastrophe’s aftermath it will be more vital than ever to ensure global supply chains are resilient enough to anticipate and respond to natural disasters, disruptive events, game-changing technologies, and other industry-altering phenomena.

Infographic Sources

Foley & Lardner, “Global Supply Chain Disruption and Future Strategies”